Not known Factual Statements About Curtain Wall Spandrel Panel Detail

Table of ContentsThe Best Guide To Gable Spandrel PanelThe Best Guide To Aluminum Spandrel Panel3 Simple Techniques For Secondary Glazing PanelsThe 9-Minute Rule for Aluminium Spandrel PanelThe Main Principles Of Replacement Double Glazing Panels Prices 7 Simple Techniques For Replacement Double Pane Glass Panels

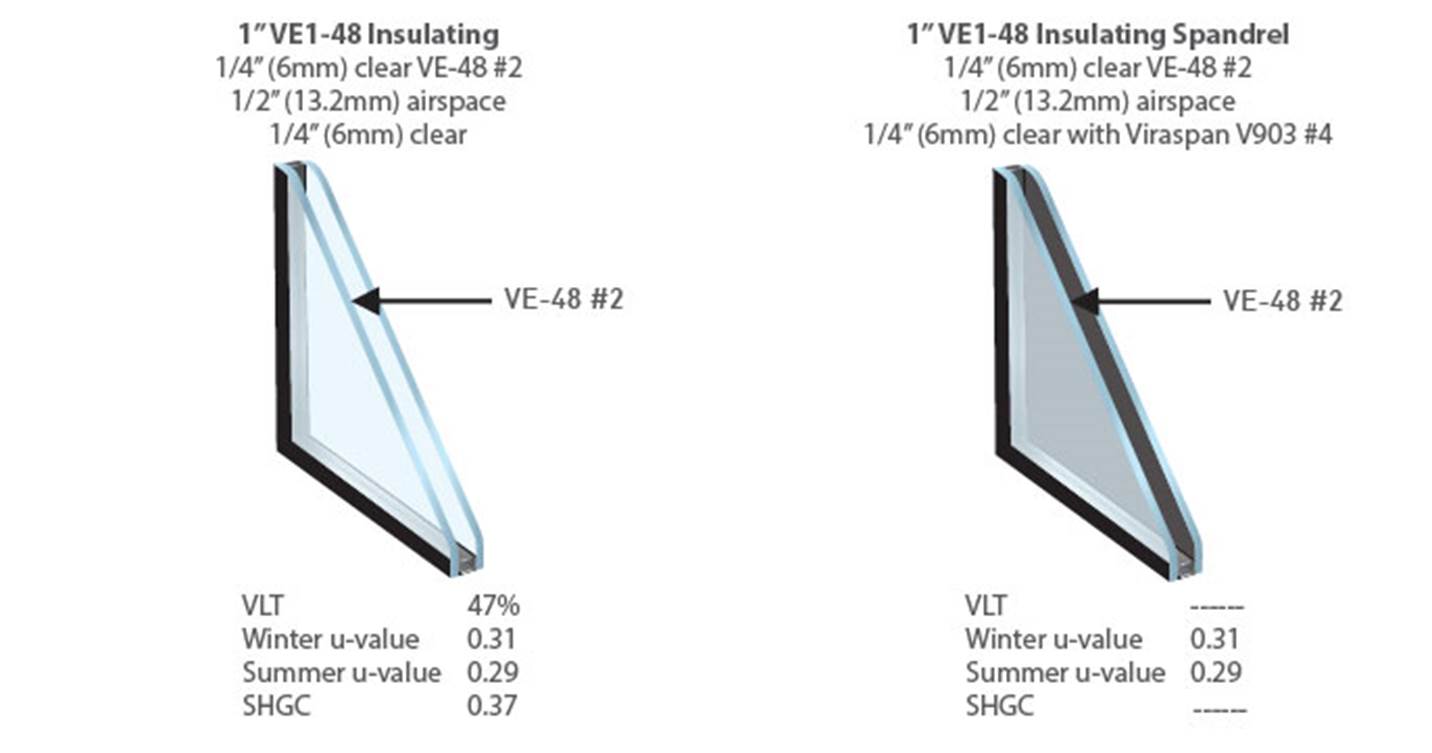

Sometimes, there are concerns associating with having way too much uncontrolled daylight, in some cases referred to as glare. The obstacle is to strive for the greatest visible light transmittance (VT) and also the most affordable solar warm gain coefficient (SHGC) while not protecting against the glass from being as well reflective when watched from both the outside as well as the inside, while managing glare.The devices need to be entirely set up in a manufacturing facility and delivered to the site for installation on the structure. The systems are placed on the floorings, packed in dog crates, using the tower crane and also lowered into place utilizing a smaller crane or raise possessed by the glazing contractor. The mullion dimensions tend to be slightly bigger than a stick system because of their open section as compared to the tube form of a typical stick drape wall section.

Units can be set up in a factory while the architectural framework of the structure is being created. Where stick systems require multiple actions to erect as well as secure the wall surface, unitized wall surfaces get here on the website entirely assembled allowing the floors to be closed in quicker (aluminum spandrel panel). Unitized systems additionally call for less room on site for format hence supplying an advantage for metropolitan websites with area limitations.

Some Ideas on Aluminium Spandrel Panel You Need To Know

The interlocking upright mullions will typically have two interlocking legs. One leg will certainly be in the plane simply behind the glazing pocket and also the other at the interior face of the mullions. The interlocking leg in the airplane of the glazing pocket will certainly be secured by gaskets and also is the primary line of protection versus water as well as air seepage.

Equipments whose linking legs lock additionally jeopardize the capability of the system to fit activity. Some unitized designs are sensitive to tiny irregularities in the spacing of nearby components; as an example, if the component joints are a little out of tolerance, gaskets might not be appropriately compressed as well as moisture security may endure.

This is where field labor need to secure in between nearby systems to accomplish a weather limited wall surface. The interlocking legs of the straight mullions are the most essential user interface of a unitized system.

What Does Insulated Metal Spandrel Panels Do?

These upstanding legs have gaskets that seal versus the wall surfaces of the bottom straight. Some designs offer one honest leg that provides one line of defense against air and also water seepage. Much more robust systems will certainly supply 2 upstanding legs with gaskets on both legs. A splice plate or silicone blinking that is installed at the top of the two adjacent systems as they are erected on the structure is typically required.

The stack joint is the horizontal joint where units from adjoining floors satisfy. Putting the pile joint at the sill of the vision glass (generally 30" above the floor) will certainly lessen the measurement of the vertical mullions. This positioning uses the back period of the mullion above the anchoring point at the piece to counteract the deflection of the mullion listed below the piece (replacement glazing panels).

Define that laboratory tests are to be carried out at an AAMA Accredited Lab center. Field Mock-up: For all drape wall surfaces, supply or personalized, call for building as you can find out more well as screening of a field mock-up agent of the wall/window setting up. This is ideal scheduled before the launch of shop drawings for home window manufacturing, so that there is a possibility to make layout changes based upon the examination performance of the field mock-up.

Examine This Report about Aluminum Spandrel Panel

The details related to this area of the BEDG on the WBDG were created by committee and also are meant entirely as a way to show general layout and building principles only. Suitable use and also application of the concepts illustrated in these details will vary based on performance considerations and also environmental problems special per task and also, consequently, do not stand for the last viewpoint or suggestion of the author of each area or the board members accountable for the growth of the WBDG.

Constant steel sill blinking at the base of the curtain wall protects the wall surface framing below from leakage via the drape wall surface. Sill flashing should have upturned end dams and completely secured corners. Intermediate straight must be cried to the outside as well as protect against water from draining onto the head of the glazing site here device listed below.

Some Known Details About Fire Rated Spandrel Panel

Gasket height need to correspond to the drape wall layout stress. Outside cover splice sleeves are mounted at the face of the pile joint during device area installation. Units are developed and also installed with straight as well as vertical clearance spaces to enable differential activity and fit construction resistances. Stress equalized rainscreen gaskets develop a main weather seal at the face of the unitized vertical pile joint in accordance with the straight rainscreen gasket at the system sill below.

Spandrel glass adapters are used to reduce the depth of the glazing pocket to suit decreased account of spandrel glass. Spandrel glass adapters must be fully bedded in sealer as well as integrated with polishing pocket edge seals to stop water leakage from polishing pocket to building interior. Unit measurement of mating head and also sill extruded accounts enables specified flooring to floor deflection browse this site at the stack joint.

Intermediate horizontals quit at the face of the vertical system jamb participants at each end. Systems are hung from the top or face of the adjacent floor or building structure utilizing mated brackets and also field applied screws with a minimum of clearance for access as well as assembly. All links and braces situated within the devices shielded or main weather seal zones are secured with proper sealer products during field installment.

Aluminum Spandrel Panel Can Be Fun For Everyone

non-heat-treated) or fully toughened up glass to stay in location up until it can be replaced. Whether heat-strengthened or fully tempered, heat-treated glass products are created in a comparable fashion as well as using the same processing tools. The glass is warmed to about 650 C (1200 F), then force-cooled to develop surface area and side compression.

As indicated in Number 1, insulation is often made use of along with spandrel glass. When the insulation is to be applied straight to the opacified surface area of the spandrel glass, it is necessary to deal with a glass spandrel fabricator, along with the adhesive and insulation suppliers, to make sure these products are compatible with the opacifying product. replacement double glazing panels prices.